The Ultimate Guide to Different Types of Industrial Blowers

Industrial blowers play a crucial role in various sectors, especially in the manufacturing industry. These powerful machines are designed to move air and gases through a system to enhance ventilation, deliver materials, cool machinery, and more. In this comprehensive guide, we will explore the different types of industrial blowers and their applications.

Centrifugal Blowers

Centrifugal blowers, also known as radial fans, are one of the most common types of industrial blowers. They create airflow by accelerating air radially outward. These blowers are ideal for applications requiring high airflow and medium to high pressures. Industries such as HVAC, chemical processing, and power generation benefit greatly from centrifugal blowers.

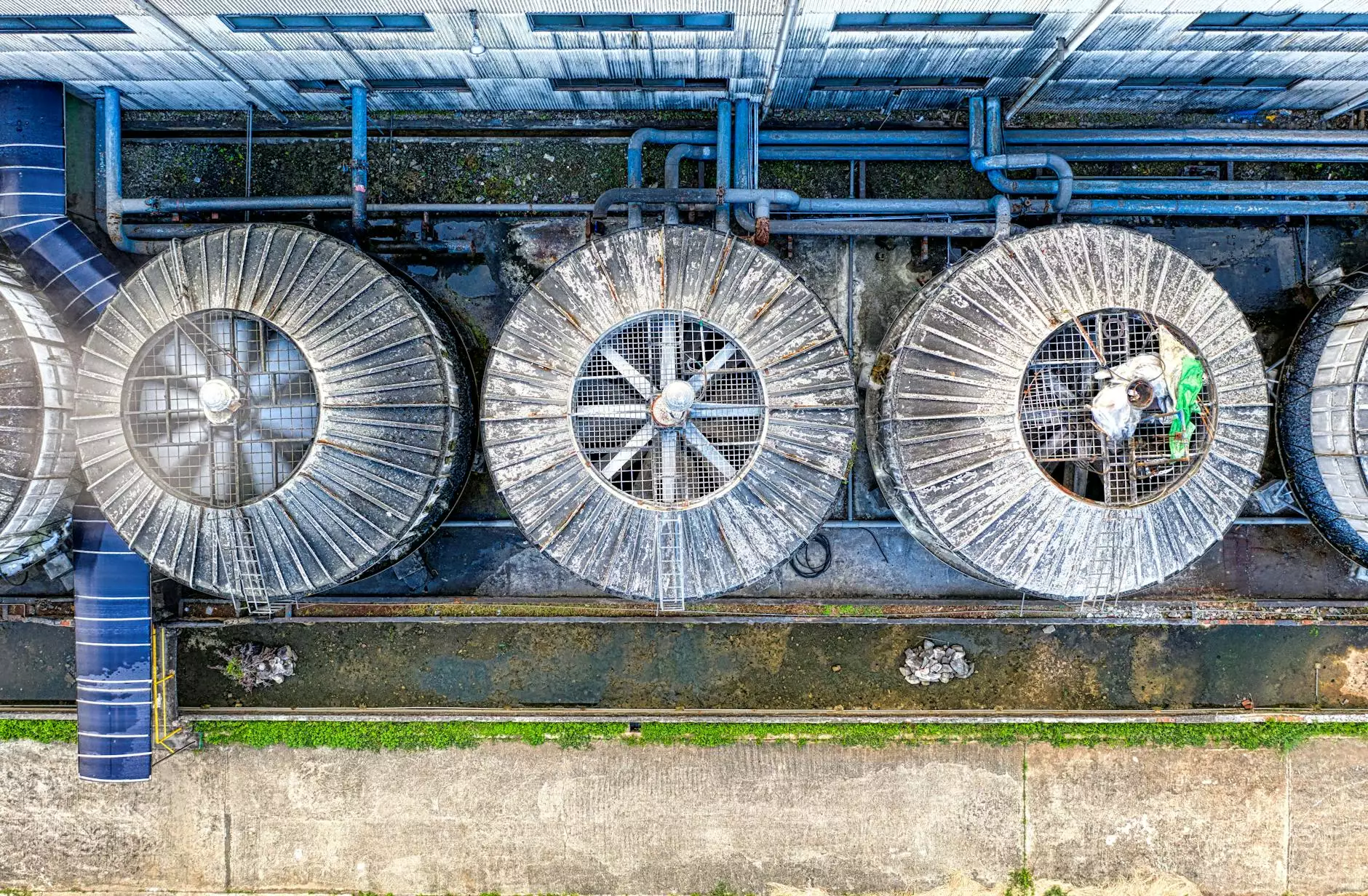

Axial Flow Fans

Axial flow fans are another popular type of industrial blower that generates airflow parallel to the fan's axis. These fans are known for their high efficiency in moving large volumes of air at low pressures. They are commonly used in applications such as cooling towers, ventilation systems, and air-cooled heat exchangers.

Positive Displacement Blowers

Positive displacement blowers operate by trapping a certain amount of air between rotating lobes and the blower housing, then pushing it out to create airflow. These blowers are ideal for applications requiring low flow rates at high pressures, such as pneumatic conveying, wastewater treatment, and aeration systems.

Multistage Centrifugal Blowers

Multistage centrifugal blowers consist of multiple impellers arranged in series to generate higher pressures and efficiencies compared to single-stage centrifugal blowers. Industries that require high-pressure air supply, such as steel production, mining, and oil and gas, often utilize multistage centrifugal blowers for their operations.

Regenerative Blowers

Regenerative blowers, also known as side-channel blowers, are compact and efficient machines that produce airflow through a process called regenerative or radial flow. These blowers are commonly used in applications where oil-free and pulsation-free air delivery is required, such as in the medical, electronics, and food processing industries.

Industrial Blower Selection Guide

When choosing an industrial blower for your specific application, it is essential to consider factors such as airflow requirements, pressure levels, material compatibility, efficiency, noise levels, and maintenance needs. Consulting with a reputable blower manufacturer or supplier can help you make an informed decision based on your requirements.

Conclusion

Industrial blowers come in a variety of types, each with its unique design and performance characteristics. Understanding the different types of industrial blowers can help you select the right solution for your business needs. Whether you are in the manufacturing, healthcare, or any other industry that relies on efficient air movement, choosing the right blower can significantly impact your operations.

industrial blower types